Cellular machines are inspired from biology, where DNA, amino acids, and proteins all illustrate systems where a complex structure is formed from a small set of discrete, interlocking, basic building blocks. Since these "voxels" must self-align and interlock with those around them, the overall accuracy is determined by the individual voxels, which can be made very precisely using microfabrication techniques. This phenomenon is analogous to a child with crude finger positioning assembling a Lego structure with five micron precision. Inherent to the success of this technology is a fabricator that can rapidly assemble millions of voxels in a parallel, top-down approach. This deterministic control allows completely arbitrary 3D multi-material microfabrication.

|

|

Imagine a desktop fabricator capable of making perfectly repeatable, arbitrary, multi material 3D objects with microscale precision. The objects would be composed of millions or even billions of small physical building blocks ("voxels"). Some building blocks could be hard, some could be soft. Some could be red, others green or blue. Some could be conductive and others could perform computation or store energy. Some could even be sensors and others actuators, and so on and so forth. With a relatively small repertoire of building block types and a rapid assembler, one could assemble a relatively large variety of machines at high resolution. How would that work?

|

|

In the digital domain, a 3D object is composed of repeating, fundamental building blocks which we call "voxels" (volumetric pixels). Each voxel location is either occupied (1) or not (0), so 3D space is digital (discrete) instead of analog (continuous). All current manufacturing processes (even digitally controlled CNC machines) are fundamentally analog. Over the past several decades, the transition from analog to digital has revolutionized many fields, most notably computing and communication. Many of the advantages gained here translate to digital matter, such as perfect repeatability with no noise and better precision than the assembly machine. However, a finite resolution must be chosen, and processing time increases.

|

|

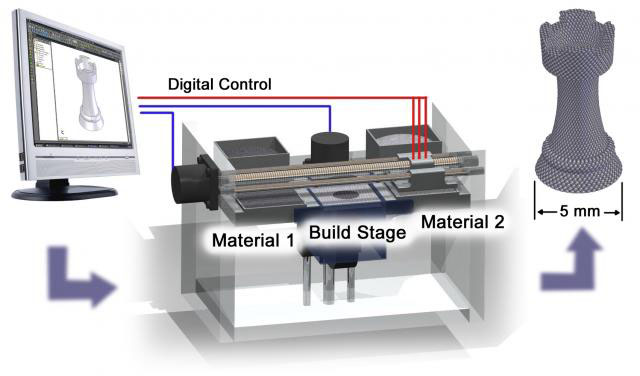

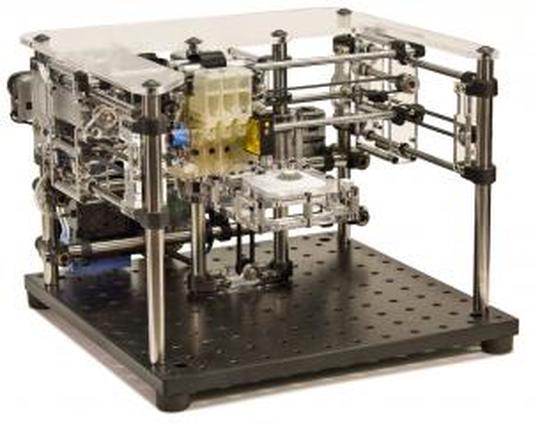

Just like inkjet printers scan continuously and deposit drops of ink into paper, the VoxJet deposits physical voxels (or 3D pixels) to create 3D digital matter. This research platform is capable of depositing a 3D lattice of small spheres at a continuous deposition rate of ten spheres per second. Up to three materials may be combined in any configuration. An integrated binder deposition system and non-contact laser feedback system enable robust, repeatable results.

The voxjet has been used to demonstrate fully recyclable multi-material 3D printing. In this process, voxels of multiple materials are printed and bound together by a reversible binder. When it's no longer wanted, the bonds holding the spheres together are reversed (in this case using water-soluble glue), and the individual spheres are reclaimed and fed back into the machine. A second technology based on the paradigm of laser printing is also being developed, which has the ability to place an entire layer of voxels simultaneously. |

|

As thousands and millions of individual physical voxels are combined together in a build process, it is important to characterize how they behave. We are exploring the unique possibilities enabled by having deterministic control over the internal material distribution of a solid. The fact that a digital fabrication process can inherently combine materials of a wide range of material properties has far-reaching implications in the realm of tunable materials. For instance, randomly combining stiff and flexible voxels yields a material with an intermediate stiffness which can be controlled purely by the ratio of the two materials. Using the concept of voxel microstructure, non-intuitive properties such as negative Poisson's ratio can be obtained.

As more voxels are added, dimensional random errors tend to cancel and the error of a structure grows sub-linearly to create very precise objects. When a system of voxels interlocks positively the error is practically constant no matter the size of the structure. Practically, this means that a digital fabricator can fabricate objects that are more precise than its own positioning system and scale to many, many voxels. |

Project participants |

|

Related Publications |

|