|

|

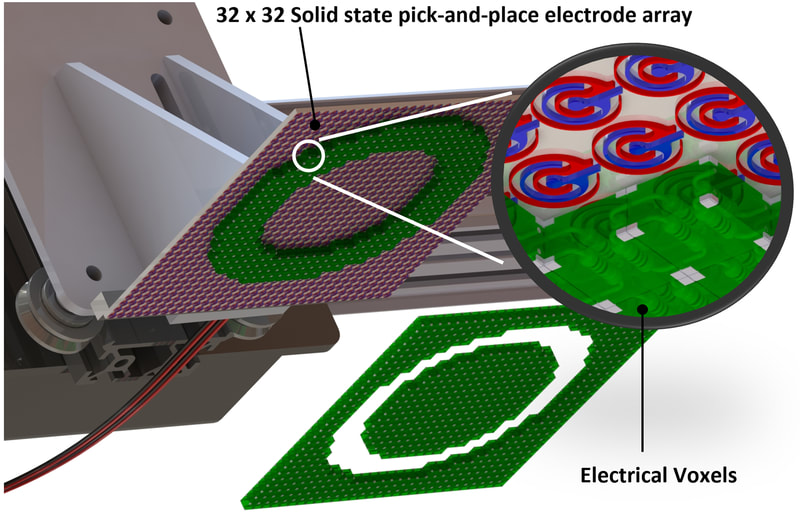

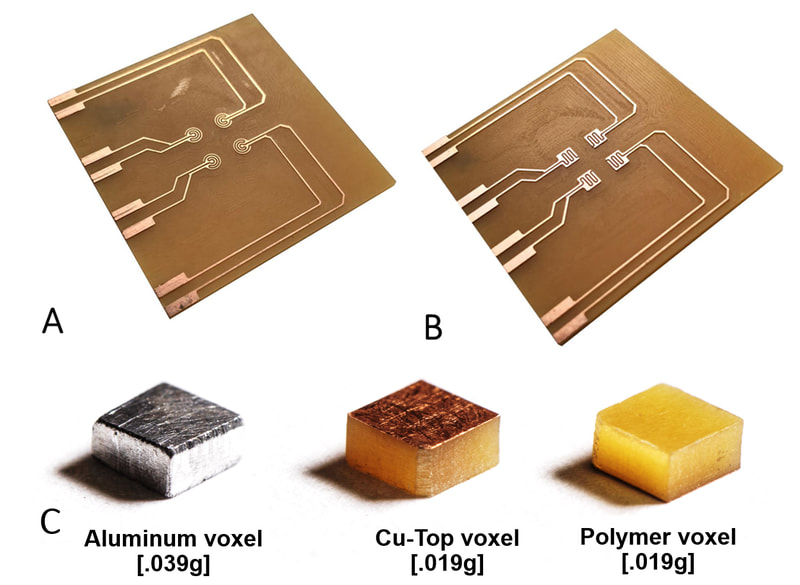

Present day pick-and-place robotic grippers position intended objects in mostly serial succession and, as a result, have plateaued in assembly speed, all the while remaining one the most expensive pieces of equipment in the PCB assembly process. Leading Surface Mount Technology [SMT], can place up to 104,000 components per hour by employing some parallel grasping couple of components. Layered Assembly addresses the speed bottleneck by grasping voxels in parallel and the multi-material limitation by the inherent capability of multi-material grasping.

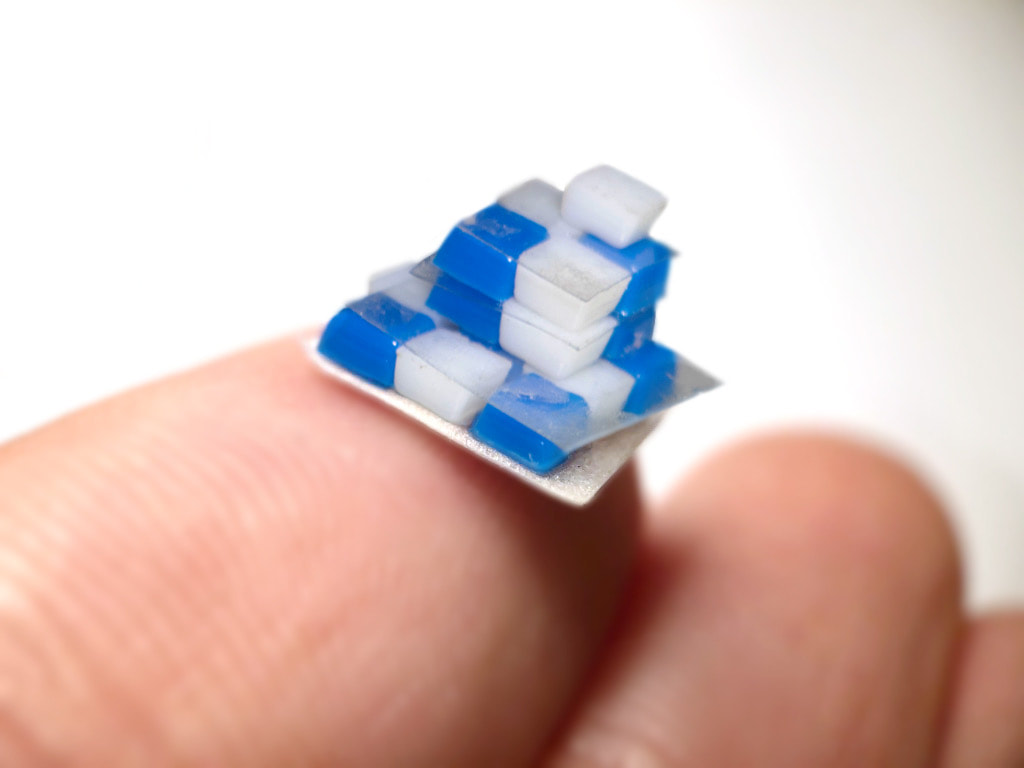

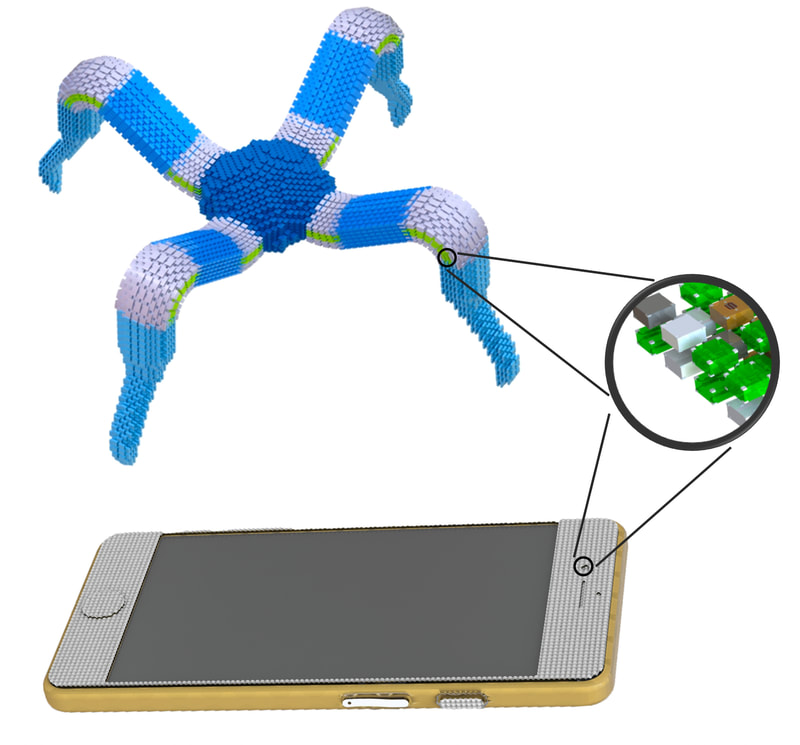

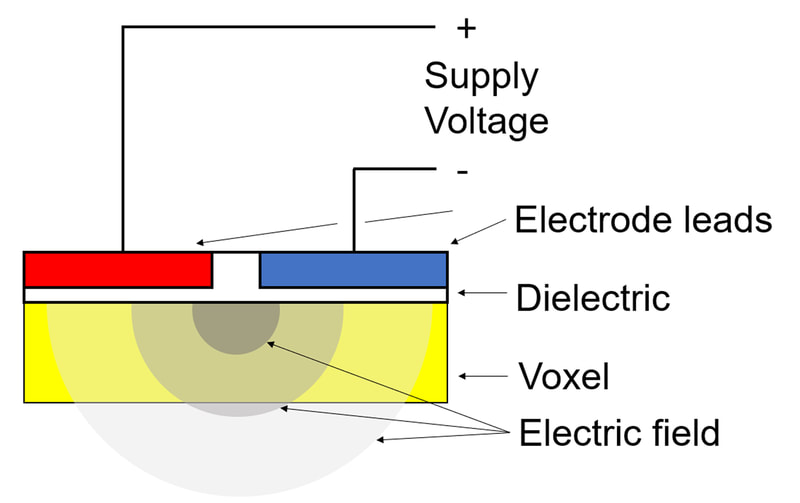

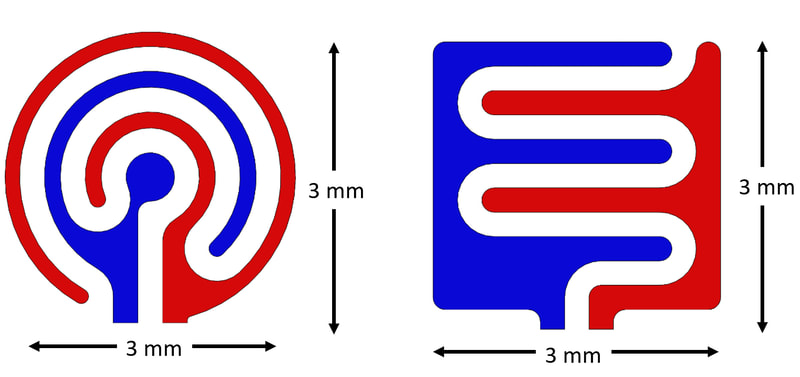

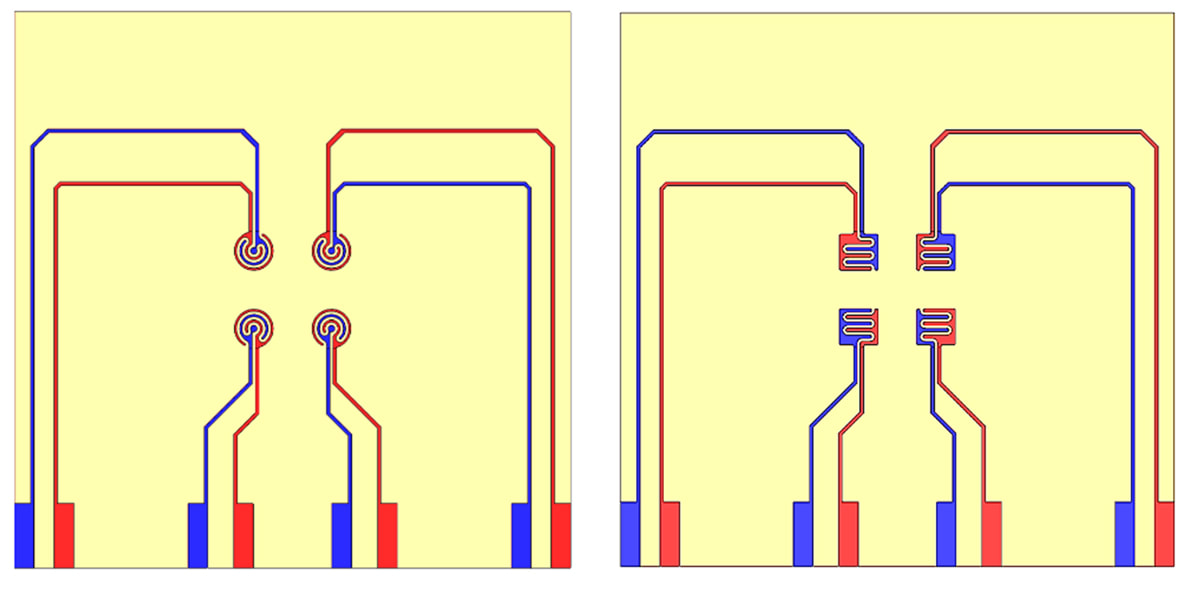

Layered Assembly is an additive manufacturing method which systematically builds multi-material parts through layer-by-layer deposition of 3D building blocks knowns as “voxels”. By using voxels in place of the raw material, Layered Assembly fundamentally differs from established AM processes in how the raw material is shaped, manufactured, assembled, and ultimately thought about in design paradigms. The discrete and digital nature of the voxels used in Layered Assembly, starkly contrast the continuous filament, resin, or powder melt pools used in established AM processes. Lastly, and most importantly, Layered Assembly differs from existing multi-material AM methods because it enables the co-fabrication of parts comprised of both metals and polymers in the same build tray. |

Related Publications |

|