|

|

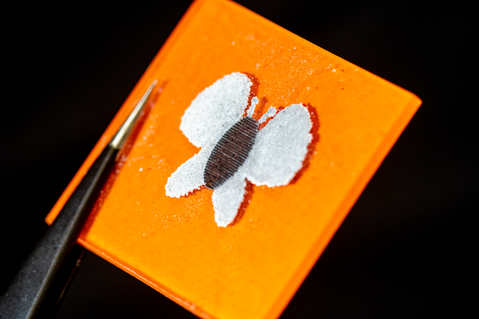

The inverted nature of this process allows for direct monitoring and observation of the part as it is being printed, to ensure any defects are caught early in the process. Additionally, passive material that previously acted only as support is no longer necessary, reducing the amount of powder that needs to be exposed to a heated environment. Furthermore, we have found that direct compression of the monolayer prior to processing has a direct effect on layer strength. This enables the part to have an artificially weaker region to enable failure predictions, or to be uniformly more robust.

|

|

|

|

Project Participants:

|

John Whitehead, Hod Lipson

|

|

Publications:

|

|

|

Press:

|