|

|

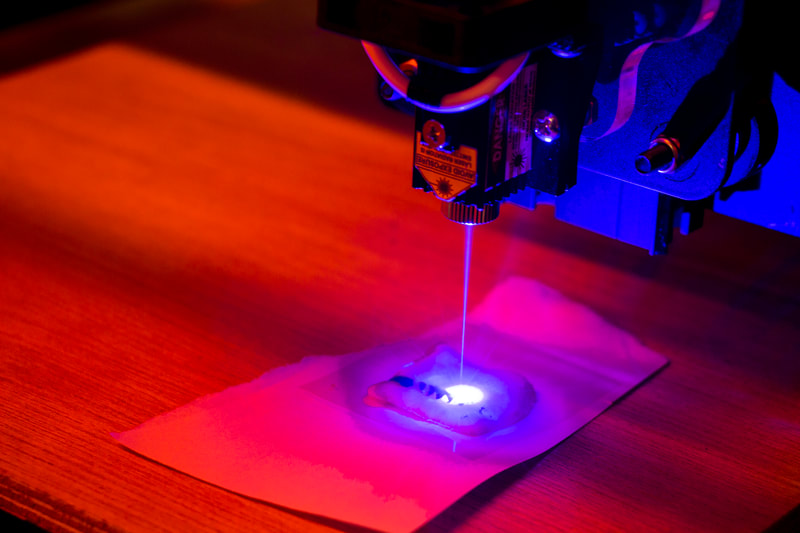

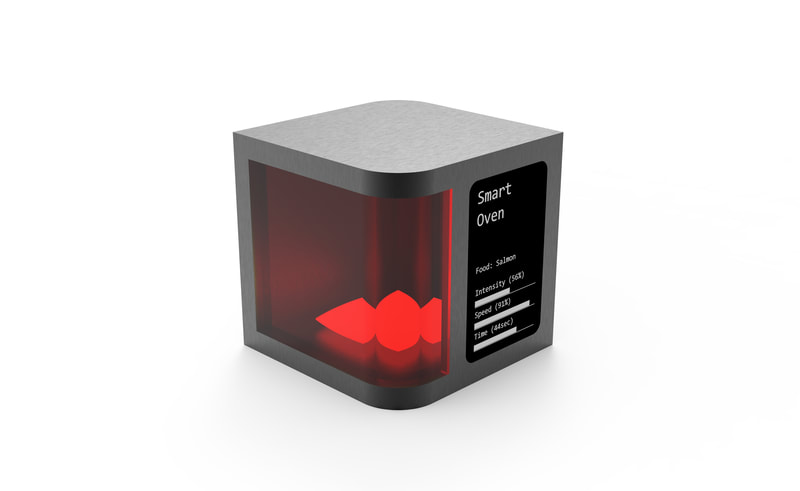

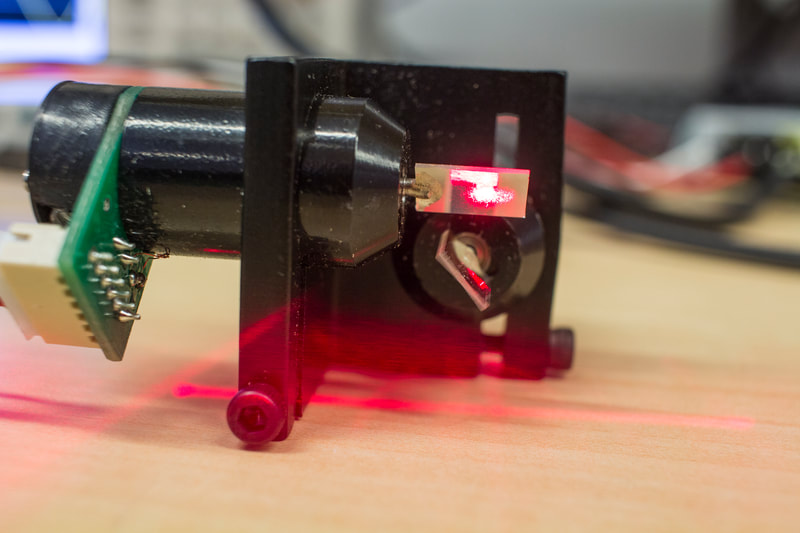

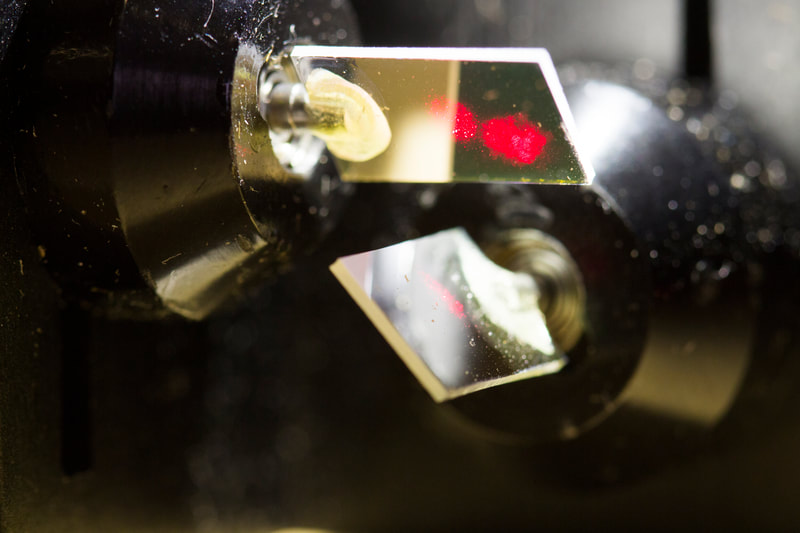

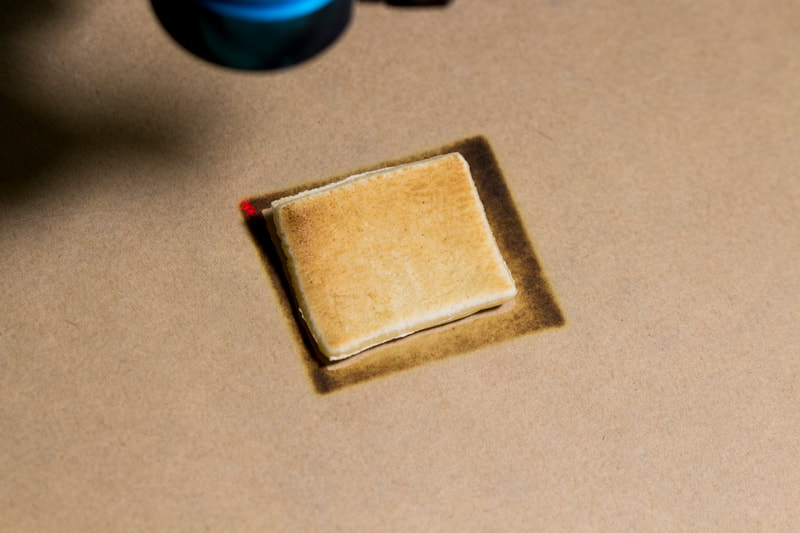

Laser cooking is a software-controlled cooking technique that uses the heat from lasers to cook food products. Because lasers can provide precise spatial and temporal control of heat, we can tailor the heating and fine tune parameters such as laser power, exposure time, light wavelength, and a host of other variables to optimize heating to achieve desired cooking for different foods.

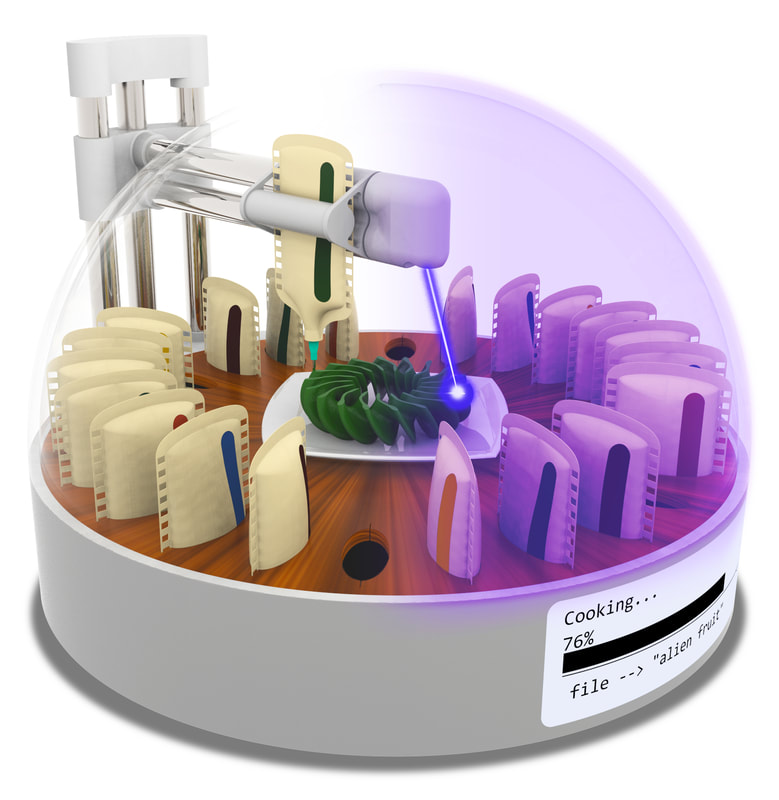

While this technology could be used as an augment to other cooking appliances (i.e. in a microwave for controlled browning on the surface of foods), it's high-fidelity and low thermal penetration make it an ideal candidate for a food printing application. Integrating this technology with a food printer would provide end-to-end cooking and personalized meal creation on a per person basis. |

|

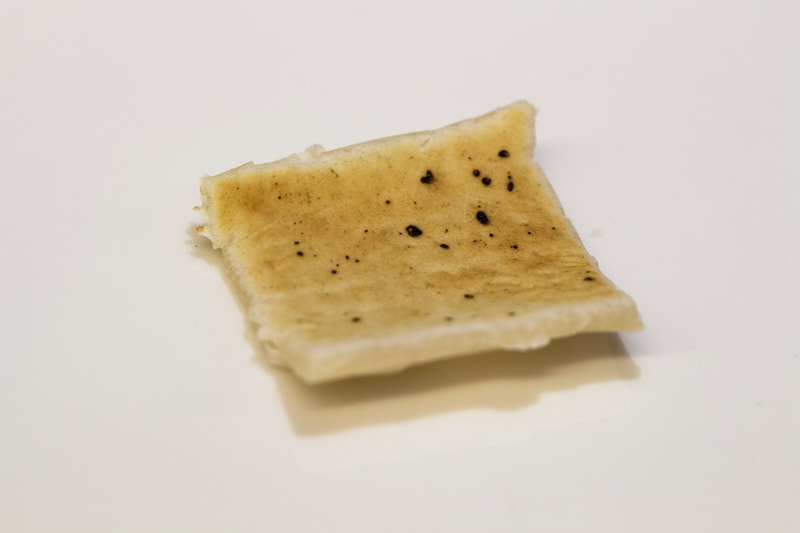

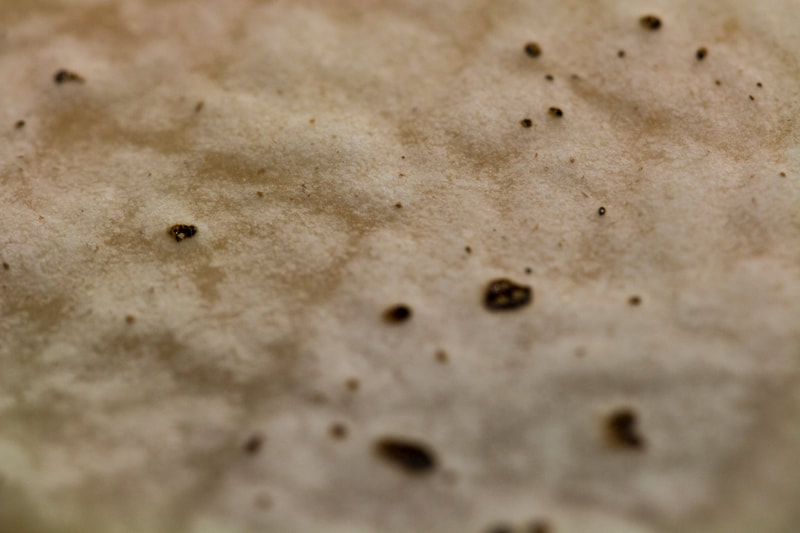

Thus far, we have been investigating the heating effects of mid-infrared lasers (10.6 microns), near-infrared lasers (980 nm), and blue lasers (445 nm) on various foods; namely, dough, chicken, salmon, and vegetables.

Wavelength of the laser light being used for cooking is a key determinant for depth of heat penetration in laser-cooked foods. Through our studies (below), we found Infrared lasers are best for browning the surface of foods and blue lasers are more well suited for penetrative cooking. Multiple laser wavelengths should be used for optimal cooking. |

|

Project participants |

Jonathan Blutinger, Yorán Meijers, Gabriel Seymour, Steven Cardenas, Elise Liu, Alissa Tsai, Erika Storvick, and Hod Lipson

|

RELATED PUBLICATIONS |

|